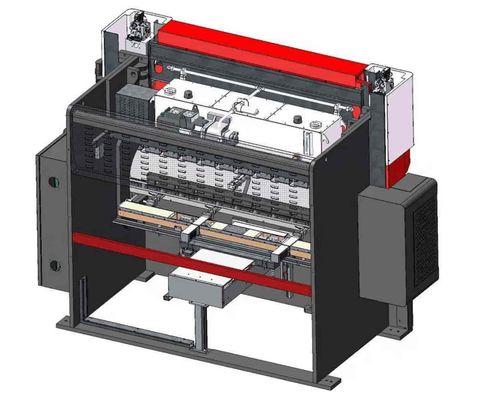

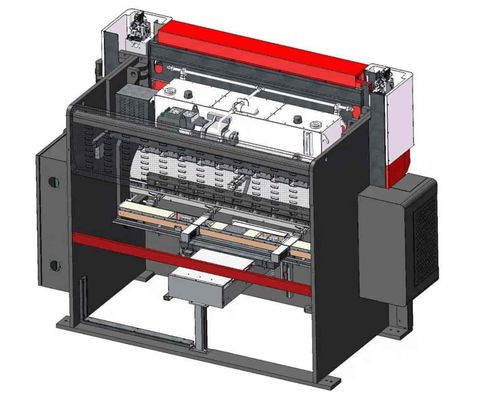

Cnc Press Brake Machine 63t 2500mm da52s DA69T 3+1 axis 4+1 axis By Durmapress EHC1303

Essential details

| No. |

Name |

Specification |

Measure Unit |

| 1 |

A (Length) |

3680 |

mm |

| 2 |

B (Width) |

1630 |

mm |

| 3 |

C (Height) |

2780 |

mm |

| 4 |

D (Installation width) |

3080 |

mm |

| 5 |

E (Throat depth) |

390 |

mm |

| 6 |

F (Opening height) |

470 |

mm |

| 7 |

G (Distance between lower and upper table) |

350 |

mm |

| 8 |

H (Upper worktable height) |

950 |

mm |

| 9 |

Capacity |

130 |

ton |

| 10 |

Bending length |

3000 |

mm |

| 11 |

Stroke |

200 |

mm |

| 12 |

Back gauge stroke |

600 |

mm |

| 13 |

Total power |

12.4 |

kw |

| 14 |

Total weight |

8.1 |

ton |

| 15 |

Number of axis |

4+1 |

axis |

| 16 |

Accuracy of axis Y1/Y2 |

±0.01 |

mm |

| 17 |

Accuracy of axis X |

±0.01 |

mm |

| 18 |

Accuracy of axis R |

±0.1 |

mm |

| 19 |

Approach speed of axis Y1/Y2 |

200 |

mm/s |

| 20 |

Bending speed of axis Y1/ Y2 |

0.2-15 |

mm/s |

| 21 |

Return speed of axis Y1/ Y2 |

200 |

mm/s |

| 22 |

Moving speed of axis X |

500 |

mm/s |

| 23 |

Moving speed of axis R |

62 |

mm/s |

| 24 |

Hydraulic oil |

200 |

L |

1. Key Components Configuration List

| No. |

Name |

Set |

Manufacture |

| 1 |

CNC Controller |

1 |

STEP(Italy) / Delem

(Netherlands)

|

| 2 |

Foot switch |

1 |

KACON(Korea) |

| 3 |

Terminal module |

3 |

JRT(China) |

| 4 |

Circuit breaker |

1 |

SCHNEIDER(Germany) |

| 5 |

Circuit breaker Switch |

1 |

SCHNEIDER(Germany) |

| 6 |

AC contactor |

1 |

SCHNEIDER(Germany) |

| 7 |

Relay |

1 |

SCHNEIDER(Germany) |

| 8 |

Relay socket |

1 |

SCHNEIDER(Germany) |

| 9 |

Power supply |

1 |

DELTA(Taiwan) |

| 10 |

Servo hydraulic system(Y axis) |

2 |

EKO(China) |

| 11 |

Motor driver + Servo motor

(Back gauge)

|

4 |

MITSUBISHI(Japan) |

| 12 |

Sensor |

4 |

OMRON(Japan) |

| 13 |

Screw + Rail(back gauge) |

6 |

HIWIN(Taiwan) |

| 14 |

Bearing |

7 |

NSK(Japan) |

| 15 |

Crowning system |

1 |

EKO(China) |

| 16 |

Frame + Sliding table |

1 |

EKO(China) |

| 17 |

Servo reducer |

2 |

HARMONIC (Japan) |

| 18 |

Motion controller |

2 |

STEP(Italy) / Delem

(Netherlands)

|

| 19 |

Key switch |

1 |

KACON (Korea) |

| 20 |

Emergency stop switch |

1 |

KACON (Korea) |

| 21 |

Buzzer |

1 |

KACON (Korea) |

| 22 |

Power Indicator |

1 |

KACON (Korea) |

Mould components

The assembly unit consists of the upper and lower mould assembly. The upper mould is fixed on the upper table by the clamping device; the clamping device provided by the device realizes quick loading and unloading of moulds through a mechanism. The clamping device is provided with a wedge trimming mechanism for locally modifying the bending angle so that the angle of workpiece is changed within the tolerance range. The lower mould, together with the mould sea and rail guide, is arranged on the lower table.

5. CNC Controller

Delem and STEP Controller please reference by the documents of DA-66T_English, DA-69T_English and STEP_English.

6. Hoisting and installation

(1) Hoisting

The center of gravity of the machine is slightly forward and on the high side, so it is necessary to pay attention to the position of center of gravity of the machine tool during lifting, handling and installation so as to avoid overturning of machine tool. During hoisting, the lifting appliance must be fixed on the hoisting hole of machine tool for vertical hoisting. For transportation, the equipment must be firmly fixed with a bandage.

(2) Installation and leveling

As indicated in the attached drawing (foundation drawing), make the machine tool installation base in advance, put the machine tool on the base, and install the foundation bolts and foot-pad steel plate. Meanwhile, confirm the level of the rack, with the lower table surface as the baseline. Adjust the bolts of base anchor to make the levelness in the vertical and horizontal direction≤1000:0.20. To adjust the levelness of machine tool in both vertical and horizontal direction to reach the requirement.

(3) Requirements for external connection cable

For the safety of machine and operators, a 100A three-phase air circuit breaker must be installed 2 for externally connected power supply, and the cable is required to be 4-core RV wire ≥10mm . In addition, the grounding device needs to be set independently and cannot be shared with other electrical circuits, with resistance value ≤ 4 Ω.

7. Maintenance

Specifications on daily maintenance of hydraulic press brake.

In order to ensure good performance and precision of equipment during production, guarantee product quality, reduce maintenance frequency and prolong the service life, it is required to strictly carry out daily inspection items, e.g., dust and rust removal, moisture prevention, lubrication, screw tightening, etc.

Sliding table bearing and lifting bearing shall be lubricated, checked and tightened, and lubrication oil replaced every two months (oil grease resistant to 200℃ high temperature shall be used).

Major parts such as the screw rod, siding rail, mould seat, upper and lower table shall be subject to dust and rust removal every two days;

Movable parts, such as screw rod, guide rail, shall be lubricated, checked and tightened every month.

Electrical parts shall be subject to dust removal, checked and tightened once a week.

EKO Equipment Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system. Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.EKO Equipment Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system.

Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.

FAQ:

How long does it take to deliver the machine?

Generally, we will deliver the goods within 30 days. If the machine belongs to non-standard customized products, the time will be longer, but the longest time will not exceed 50 days.

What is the warranty period of your machine?

For conventional machines, our warranty period is one year. For special non-standard machines, we may provide a 2-3 year warranty, but this should be confirmed with our sales team in advance. During the warranty period, we provide free replacement parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!