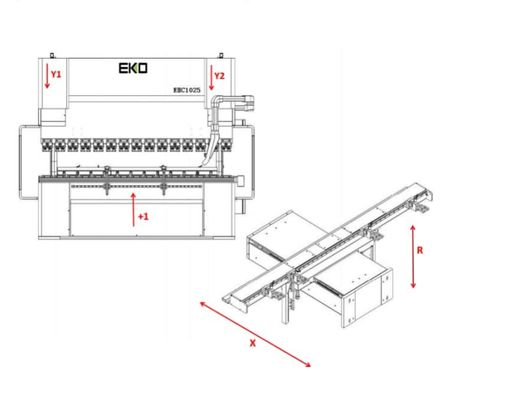

Hydraulic Press Brake 100T2500 Hydraulic Bending Machine Press Brake Cnc Metal Steel Bending Machine Steel EHC1025

Essential details:

| Slider Stroke (mm): |

Applicable Industries: |

|

200 mm

|

Hotels, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works

|

| |

|

| Automatic Level: |

Showroom Location: |

|

Fully Automatic

|

Viet Nam, Russia, Thailand, South Korea, Malaysia, Australia, New Zealand

|

| |

|

| Throat Depth (mm): |

Marketing Type: |

|

295 mm

|

Hot Product 2020

|

| |

|

| Machine Type: |

Machinery Test Report: |

|

Synchronized, Press brake

|

Provided

|

| |

|

| Length of Working Table (mm): |

Video outgoing-inspection: |

|

2500

|

Provided

|

| |

|

| Width of Working Table (mm): |

Warranty of core components: |

|

1600 mm

|

1 Year

|

| |

|

| Dimension: |

Core Components: |

|

3060*1530*2630

|

Bearing, Motor, Pump, Gear

|

| |

|

| Condition: |

Product name: |

|

New

|

EHC1025 CNC Hydraulic Press Brake

|

| |

|

| Place of Origin: |

Model: |

|

Guangdong, China

|

EHC1025

|

| |

|

| Brand Name: |

Type: |

|

EKO

|

Hydraulic

|

| |

|

| Material / Metal Processed: |

Control system: |

|

Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

|

STEP/Delem

|

| |

|

| Automation: |

Application: |

|

Automatic

|

Metal Sheet Bending

|

| |

|

| Weight (KG): |

Feature: |

|

6500

|

High efficiency, high accuracy, stable, energy-saving

|

| |

|

| Motor Power (kw): |

Number of axis: |

|

12.25 kw

|

4+1

|

| |

|

| Key Selling Points: |

Accuracy of axis D: |

|

High Safety Level

|

±0.01

|

| |

|

| Warranty: |

Bending speed of axis D1/D2: |

|

1 Year

|

0.2-15mm/s

|

| |

|

| |

Hydraulic Oil: |

| |

180L

|

EKO Equipment Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system. Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.EKO Equipment Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system.

Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.

FAQ:

Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when

(1) we have received your deposit,

(2) we have your final approval for your products. If

our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!