2022 Hot-sale Electric Press Brake EKO Brand Hot Sale New Design Heavy Duty CNC Electric Press Brake ES1253

| No. |

Name |

Specification |

Measure Unit |

| 1 |

A (Length) |

3450 |

mm |

| 2 |

B (Width) |

1680 |

mm |

| 3 |

C (Height) |

2930 |

mm |

| 4 |

D (Opening height) |

500 |

mm |

| 5 |

E (Height in operation) |

380 |

mm |

| 6 |

F (Throat depth) |

465 |

mm |

| 7 |

G (Lower worktable length) |

2440 |

mm |

| 8 |

H (Lower worktable height) |

960 |

mm |

| 9 |

Capacity |

125 |

ton |

| 10 |

Bending length |

3000 |

mm |

| 11 |

Stroke |

200 |

mm |

| 12 |

Back gauge stroke |

600 |

mm |

| 13 |

Total power |

31.8 |

kw |

| 14 |

Total weight |

13.5 |

ton |

| 15 |

Number of axis |

6 |

axis |

| 16 |

Accuracy of axis D1/D2 |

±0.005 |

mm |

| 17 |

Accuracy of axis L |

±0.01 |

mm |

| 18 |

Accuracy of axis Z |

±0.1 |

mm |

| 19 |

Accuracy of axis Y1/Y2 |

±0.1 |

mm |

| 20 |

Approach speed of axis D1/D2 |

120 |

mm/s |

| 21 |

Bending speed of axis D1/ D2 |

0.2-50 |

mm/s |

| 22 |

Return speed of axis D1/ D2 |

120 |

mm/s |

| 23 |

Moving speed of axis L |

500 |

mm/s |

| 24 |

Moving speed of axis Z |

62 |

mm/s |

| 25 |

Moving speed of axis Y1/Y2 |

700 |

mm/s |

Key Components Configuration List

| No. |

Name |

Set |

Manufacture |

| 1 |

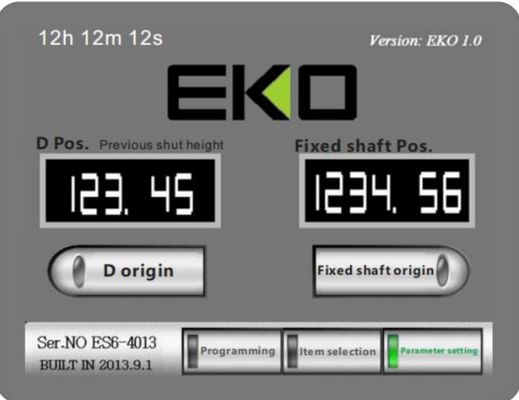

CNC Controller(NC Max) |

1 |

EKO(China) |

| 2 |

Foot switch |

1 |

KACON(Korea) |

| 3 |

Terminal module |

3 |

FALINK(Taiwan) |

| 4 |

Circuit breaker |

1 |

SCHNEIDER(Germany) |

| 5 |

Circuit breaker Switch |

1 |

SCHNEIDER(Germany) |

| 6 |

AC contactor |

3 |

SCHNEIDER(Germany) |

| 7 |

Relay |

1 |

SCHNEIDER(Germany) |

| 8 |

Relay socket |

1 |

SCHNEIDER(Germany) |

| 9 |

Power supply |

1 |

DELTA(Taiwan) |

| 10 |

Motor driver + Servo motor

(D axis)

|

2 |

SANYO(Japan) |

| 11 |

Motor driver + Servo motor

(Back gauge)

|

4 |

MITSUBISHI(Japan) |

| 12 |

Sensor |

11 |

OMRON(Japan) |

| 13 |

Ball screw(D axis) |

2 |

IF(Germany) |

| 14 |

Screw + Rail(back gauge) |

6 |

HIWIN(Taiwan) |

| 15 |

Bearing |

15 |

NSK(Japan) |

| 16 |

Timing belt |

2 |

OPTIBELT(Germany) |

| 17 |

Motor reducer (D axis) |

2 |

ALPHA(Germany) |

| 18 |

Frame + Upper table

(Q345E Steel+ 16 Manganese Steel)

|

1 |

(China) |

Main structure and working principle

The machine is a 6-axis (D1, D2, Y1, Y2, Z and L) full-servo press brake, dispense with hydraulic oil, free from the influence of oil temperature variation on the workpiece, and the machi -ne tool is more precise, energysaving and efficient than the oil press. It is mainly composed of the following components:

l Frame body

The component comprises a frame, the upper and lower table, transmission screw rod, support bearing group, guide wheel group, etc. The transmission screw rod is connected with the upper table and the frame through bolts, the servo motor drives the screw rod to rotate upper table rapidly with reciprocating motion, for the purpose of bending and forming moulds. The two groups of transmission screw rods can be independently controlled, and the angle deviation, if any, can be automatically compensated, so that the angle change of the workpiece is controlled within the tolerance range.

l Back gauge system

The assembly unit comprises lifting component, sliding table component, material retaining component, etc. The positioning system of back gauge of the machine tool is all driven by a servo motor through precision screw rod, can quickly reach the specified position, up to micron-level precision, finally realize full automation and improve the working efficiency.

l Mould components

The assembly unit consists of the upper and lower mould assembly. The upper mould is fixed on the upper table by the clamping device; the clamping device provided by the device realizes quick loading and unloading of moulds through a mechanism. The clamping device is provided with a wedge trimming mechanism for locally modifying the bending angle so that the angle of workpiece is changed within the tolerance range. The lower mould, together with the mould sea and rail guide, is arranged on the lower table.

EKO Equipment Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system. Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.EKO Equipment Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system.

Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.

FAQ:

What kind of payment do you accept?

Generally, we accept T/T and L/C payment, 30% deposit and 70% payment before delivery. If you are our special customer, we can accept better payment method.

What is the warranty period of your machine?

For conventional machines, our warranty period is one year. For special non-standard machines, we may provide a 2-3 year warranty, but this should be con

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!