4. Main structure and working principle

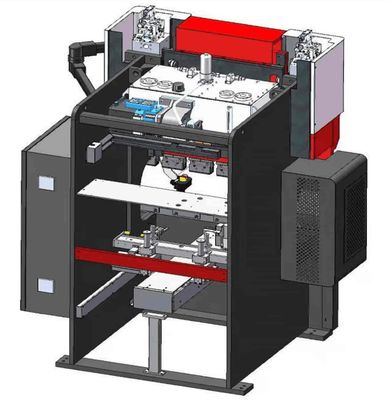

The machine is a 6axis (Y1, Y2, Z1, Z2, X, R) hydraulicpress brake.Each continuously precise and stable pure servo motor driven high-quality, high-precision press brake has an imported servo motor as its driving motive power, which is the guarantee for precise and stable moving of the equipment. It is mainly composed of the following components:

Frame body

The component comprises a frame, the upper and lower table, transmission screw rod, support bearing group, guide wheel group, etc. The transmission screw rod is connected with the upper table and the frame through bolts, the servo motor drives the screw rod to rotate upper table rapidly with reciprocating motion, for the purpose of bending and forming molds. The two groups of transmission screw rods can be independently controlled, and the angle deviationcan be automatically compensated, so that the angle change of the workpiece is controlled within the tolerance range.

Back gauge system

The assembly unit comprises lifting component, sliding table component, material retaining component, etc. The positioning system of back gauge of the machine tool is all driven by a servo motor through precision screw rod, can quickly reach the specified position, up to micron-level precision, finally realize full automation and improve the working efficiency.

Mold components

The assembly unit consists of the upper and lower mold assembly. The upper mold is fixed on the upper table by the clamping device; the clamping device provided by the device realizes quick loading and unloading of molds through a mechanism. The clamping device is provided with a wedge trimming mechanism for locally modifying the bending angle so that the angle of workpiece is changed within the tolerance range. The lower mold, together with the mold sea and rail guide, is arranged on the lower table.

5. CNC Controller

Delem and STEP Controller please reference by the documents of DA-66T_English, DA-69T_English and STEP_English.

6. Hoisting and installation

(1)Hoisting

The center of gravity of the machine is slightly forward and on the high side, so it is necessary to pay attention to the position of center of gravity of the machine tool during lifting, handling and installation so as to avoid overturning of machine tool. During hoisting, the lifting appliance must be fixed on the hoisting hole of machine tool for vertical hoisting. For transportation, the equipment must be firmly fixed with a bandage.

(2)Installation and leveling

As indicated in the attached drawing (foundation drawing), make the machine tool installation base in advance, put the machine tool on the base, and install the foundation bolts and foot-pad steel plate. Meanwhile, confirm the level of the rack, with the lower table surface as the baseline. Adjust the bolts of base anchor to make the levelness in the vertical and horizontal direction≤1000:0.20. To adjust the levelness of machine tool in both vertical and horizontal direction to reach the requirement.

(3)Requirements for external connection cable

For the safety of machine and operators, a 100A three-phase air circuit breaker must be installed 2 for externally connected power supply, and the cable is required to be 4-core RV wire ≥10mm . In addition, the grounding device needs to be set independently and cannot be shared with other electrical circuits, with resistance value ≤ 4 Ω.

7. Maintenance

Specifications on daily maintenance of hydraulic press brake.

In order to ensure good performance and precision of equipment during production, guarantee product quality, reduce maintenance frequency and prolong the service life, it is required to strictly carry out daily inspection items, e.g., dust and rust removal, moisture prevention, lubrication, screw tightening, etc.

Sliding table bearing and lifting bearing shall be lubricated, checked and tightened, and lubrication oil replaced every two months (oil grease resistant to 200℃ high temperature shall be used).

![]()

![]()

Major parts such as the screw rod, siding rail, mold seat, upper and lower table shall be subject to dust and rust removal every two days;

Movable parts, such as screw rod, guide rail, shall be lubricated, checked and tightened every month.

Electrical parts shall be subject to dust removal, checked and tightened once a week.